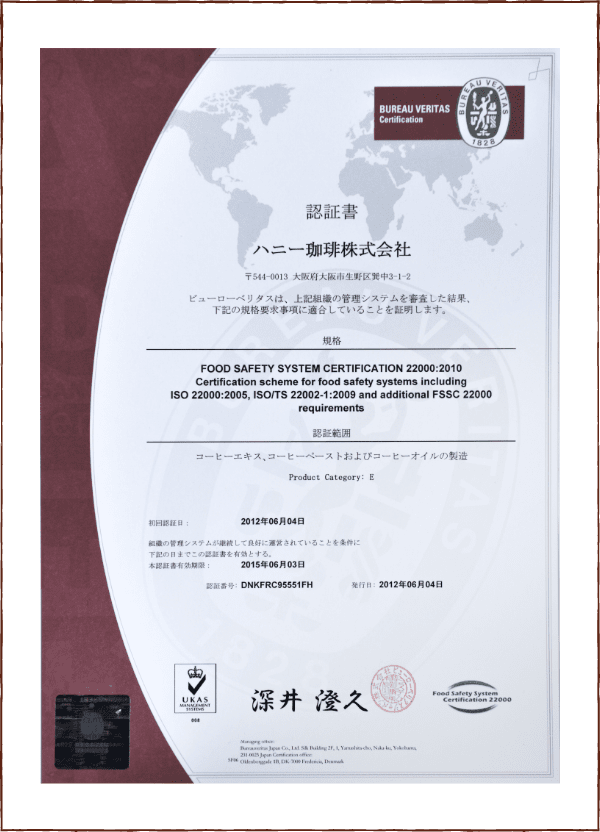

FSSC 22000 food safety system certification standard

HONEY COFFEE earned certification under the FSSC 22000 food safety system certification standard on Thursday, June 21, 2012. (The certifying organization was the System Certification Division of Bureau Veritas Japan Co., Ltd.) Certification covers the manufacture of coffee extracts, coffee pastes, and coffee oils. Reflecting our commitment not to create products we wouldn’t eat ourselves or feed to a loved one, employees came together to work towards FSSC 22000 certification in an effort to create safer products that inspire greater peace of mind, and we’ve continued to actively create our own rules since being certified. We’re also working to build a system that will allow us to smoothly manage these safety systems in-house. Going forward, we will continue to practice thorough quality control so we can supply customers with safe products that inspire peace of mind.

What is FSSC 22000?

FSSC 22000 is a food safety management system for the food manufacturing industry. As a risk management tool created by integrating ISO 22000, an international standard on food safety management systems, and PAS 220:2008, a prerequisite program (PRP) related to food safety for food manufacturers, FSSC 22000 embodies a new certification scheme for food safety businesses. It particularly centers on hazard analysis and adopts a system-wide approach to prevention.

Manufacturing site initiatives

Measures to prevent contamination

When entering the factory, workers put on the required hat, mask, and uniform in a locker room and then proceed to a handwashing room. They change into boots, run an adhesive roller over their clothing, and wash and thoroughly rinse their hands using hand soap and a fingernail brush. They then dry their hands using a dryer, sterilize their hands with alcohol sanitizer, and proceed to an air washer. The air washer removes dust, hair, and other contaminants from their persons, and then they enter the factory. Visitors follow the same protocol as workers to prevent contamination in addition to recording their name, time of entry, and state of health before entering the facility.

Tools used in the factory are managed centrally on a large dolly immediately after entering the factory. The tools are separated into process-specific storage boxes and stored on a large dolly before being placed on a small dolly and moved when used. The storage box used in each process bears the name of the responsible manager, and the types and quantities of tools used are set and carefully managed to prevent loss or hygienic problems. In the event a tool is lost at the factory, its record of use can be traced back to make it easier to find it.

Insect, rodent, and pollution countermeasures

Shipping and receiving bays at the factory have triple doors. When entering the factory from outside, the outermost door opens, and the middle door leading to the factory closes. After the delivery has been made, the outermost door closes, and the middle door leading to the factory opens, allowing the cargo to be moved to a storage space. Then the middle door closes, and the innermost door to the factory opens, allowing the cargo to be moved into the factory. Shipments from the factory follow the same process in reverse. By means of these triple doors, we carefully keep insects, foreign material, and other contaminants from outside from getting into the facility.

Each employee has separate lockers for personal clothing and work clothing. Separate storage of personal clothing ensures foreign material on such clothing does not cross-contaminate work clothing via a shared locker. In addition, work clothing is laundered after use in dedicated washing machines at the factory. The laundry drums in these machines are cleaned on a regular basis as part of an effort to practice consistent hygienic controls for work clothing.

Hazard analysis initiatives

Filters and UHT plates serve as HONEY COFFEE’s critical control points (CCPs). We strive to strengthen product safety and security through even more rigorous prevention of contamination and sterilization.

Biohazards (UHT plates)

We use UHT plates for sterilization by applying pressure to them to increase their temperature. This high-temperature sterilization process uses temperature control and set times to heat and disinfect in line with product specifications in a way that takes temperature error into account. The thermometers used to measure temperature are also carefully managed. Following sterilization, a microorganism test is carried out to test for coliform and other bacteria as well as fungal yeast, among other microbes. Products are only shipped after passing this inspection.

Physical hazards (filters)

Filters have been installed at multiple places along our manufacturing lines to prevent contamination. Filters are available in various mesh sizes, and we use three types—60 mesh, 80 mesh, and 100 mesh—in manufacturing and sterilization processes to prevent contamination. Filters are checked at a set frequency, and workers are careful to check them both before and after use. We also use magnetic filters to check for contamination with metallic material.

When filling extracts, we use an air compressor to inflate the pouch into which the extract is being filled. The tubes along which the air flows incorporate five types of filters to remove bacteria, funguses, and yeasts.

To ensure that the inlets on inner packaging don’t come into contact with air, which could allow bacteria to reproduce, the inlets are sterilized with steam before filling extract.

Groundwater from Mt. Hiei is pumped through three filtering systems, sterilized with chlorine, and stored in a 50-ton tank. Water used in the extraction process passes through a state-of-the-art reverse osmosis system to purify it by removing any impurities. Purity, residual chlorine concentration, and hardness are managed automatically and displayed on a monitor. An alarm alerts workers in the event any reference values are exceeded. The system is maintained on a regular basis by an outside testing organization.

Chemical hazards

We implement hygienic controls by means of regular CIP cleaning. After cleaning, we conduct an inspection to ensure that no detergent remains.

Factory hygiene initiatives

All equipment and stands in the factory are made of stainless steel. The material helps ensure hygienic conditions since it resists rust and dirt and is easy to clean.

Fireproof panels were used in the construction of all walls and ceilings at the factory, and waterproof power outlets were installed. The fireproof panels are flat so that they can be washed with water or pressure-cleaned to ensure cleanliness at all times.

All outside air drawn into the factory is filtered. Air entering the filling room is filtered again, and the room is maintained at positive pressure. The ceilings and walls in the filling room are constructed from easy-to-clean panels that resist dust and other dirt.

We’ve compiled lists of all locations at the factory that need to be washed or cleaned. Cleaning is performed regularly, along with post-cleaning testing, in accordance with the PDCA cycle (which consists of plan, do, check, and act steps).

Ingredient and packaging initiatives

When ingredients are delivered, we carry out the checks listed below. We also record important information including the time of delivery, name of the person making the delivery, the driver’s name, the name of the worker receiving the delivery, the day’s weather, and any potential sources of cross-contamination. We check the same items, and record the same information, when shipping products.

Delivery errors

Damage

Signs of corrective action

Presence of any foreign material

Whether the shipment was wet due to rain at the time of delivery

Checks of the interior of the truck used to transport the delivery, including temperature, cleanliness, and presence of hazardous goods

We use packaging including fiber drums, metal drums, cardboard cases, aluminum pouches, and polypropylene pouches. We can combine outer and inner packaging to suit customer requests.